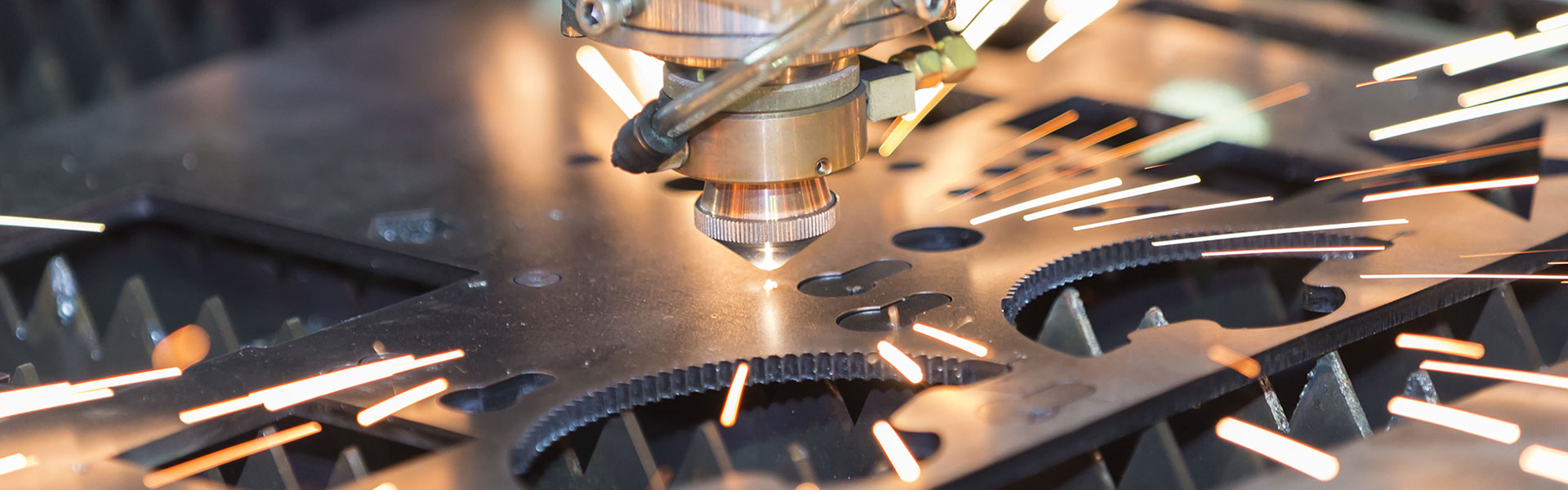

The competition in the automobile market is becoming more and more fierce, the interior design is becoming more and more abundant, and the processing technology is also continuously upgraded. More interiors use laser technology for design and production, and the application is more and more extensive. Compared with traditional manufacturing technology, laser technology has many advantages and plays an increasingly important role in design and manufacturing.

What is Laser Process?

Laser processing technology is a processing technology for cutting, welding, surface treatment, drilling and micro-machining of materials (including metals and non-metals) by using the characteristics of the interaction between laser beams and substances.

What are the advantages of laser technology?

Accurate processing: small light spot, concentrated energy, small heat affected zone;

The laser beam is easy to focus and guide for automatic control; there is no burr on the cutting surface

High efficiency: high-speed engraving and cutting can be performed immediately according to the pattern output by the computer, and the speed of laser cutting is much faster than that of wire cutting.

Less waste: Laser processing adopts computer programming, which can cut different shapes of products, maximize the utilization rate of materials, and greatly reduce the material cost of enterprises.

Non-Contact: Does not cause mechanical extrusion or mechanical stress to the material. No pollution to the workpiece.

High flexibility: not limited by the number of processing, can be processed in small batches

Extensive range: Engraving and cutting of virtually any material.

What are the applications of laser technology in automotive interiors?

The application of laser technology in interiors mainly includes cutting, texturing, marking, drilling, and surface weakening. Interior parts have its presence in many positions from the steering wheel, the instrument panel to the seats, buttons and so on.

1. Laser cutting, drilling

The material to be cut is irradiated with a high power density laser beam, the material is quickly heated to the vaporization temperature, and evaporates to form a hole. As the beam moves to the material, the hole continuously forms a narrow slit to complete the cutting of the material.

This can be achieved using continuous CO2 laser processing by evaporating low-heat, high-absorbing materials such as thin plastic films and non-melting materials such as wood, paper, and foam.

Ultrashort pulsed lasers allow the technique to be applied to other materials. Free electrons in the metal absorb the laser light and heat up violently. The laser pulses do not react with the molten particles and plasma, and the material sublimates directly, leaving no time to transfer the energy to the surrounding material in the form of heat. Picosecond pulses ablate the material without significant thermal effects, melting and burr formation.

Laser cutting processing is more precise, delicate operation, complete automatic cutting, control cutting quality, and achieve the best precision and speed of product processing. By properly controlling the power of the laser cutting machine, multi-layer precision cutting can be achieved, and flexible and fast drawing and cutting can be performed according to the interior dimensions of different models, thereby improving the flexibility of product processing and multiplying the processing efficiency of products.

2. Laser texture

The designed texture pattern is engraved on the mold by laser, and the product with texture can be produced by using this mold, and the texture pattern that cannot be achieved by traditional etching methods can be realized. Compared with the traditional etching process, the processing process is less, and the mold can be automatically processed after the software is processed.

It can process free textures on any complex 3D workpiece without worrying about process limitations, and it can also carve 3D geometric textures to present a three-dimensional effect, and is more suitable for parametric design, freeing up the creativity of designers

3. Laser marking

Laser marking is a marking method that uses a high-energy-density laser to locally irradiate the workpiece to vaporize or change the color of the surface material, thereby leaving a permanent mark.

The beam output from the laser is controlled by two mirrors mounted on a high-speed precision motor to realize the movement of the beam for marking. Each mirror moves along a single axis. The motor moves very fast, and the inertia is very small, so that the target object can be quickly marked. The beam guided by the mirror is focused by an F-theta lens with the focal point on the marked plane. When the focused beam interacts with the marked object, the object is "marked". Except for the marked position, other surfaces of the object remain unchanged.

In the processing of automotive interior products, the laser marking machine can also draw accurate and efficient graphics and texts for various automotive interior products such as leather, cloth, wood, and synthetic materials. Including logo addition, personalized graphic interpretation, wonderful carving and so on.

By laser marking graphics on seat covers, linings, steering wheels, seat belts, floor mats and other products to increase the decorativeness of the products, it can create a more refined and stylish car interior experience.

This process does not require contact with the surface of the processed item, so any profiled surface material can be marked quickly, and the workpiece will not deform and generate internal stress.

4. Surface Weakening

In the current automobile manufacturing industry, it has become a trend to integrate airbag covers into dashboards, interior door walls or other interior parts of automobiles. This new process is called "integrated airbag".

The processing method adopts the laser weakening process. The high-energy laser beam hits the instrument panel in the form of fixed-frequency pulses. The material at the focus is rapidly vaporized after absorbing the high energy of the laser, forming a penetrating or non-penetrating small holes. The thickness of the material in these small hole areas becomes thinner and the breaking strength is reduced, so that it can preferentially break when subjected to external impact. The combination of such many sequentially arranged micropores is what we usually call the airbag line.

Through the surface weakening process, the interior surface can be complete, and it can be applied to the drilling and surface weakening of parts such as automobile dashboards and door inner walls.

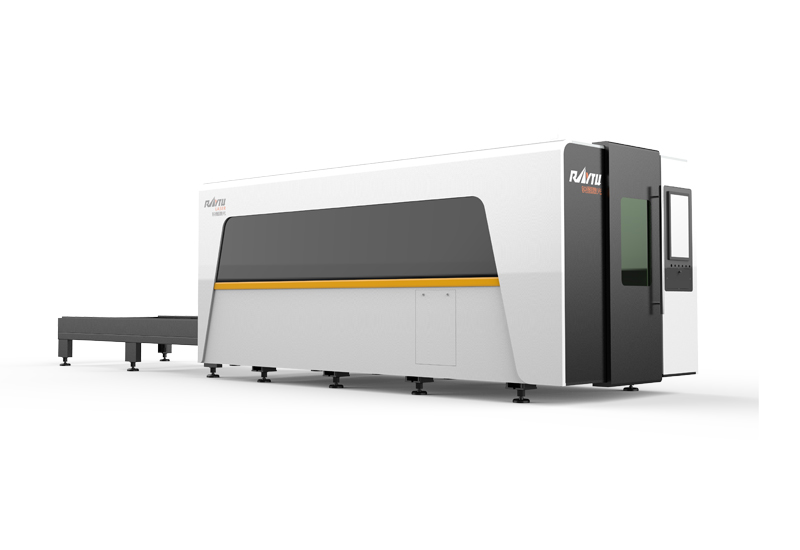

Máquina de corte por láser de fibra de alta potencia

Máquina de corte por láser de fibra de alta potencia

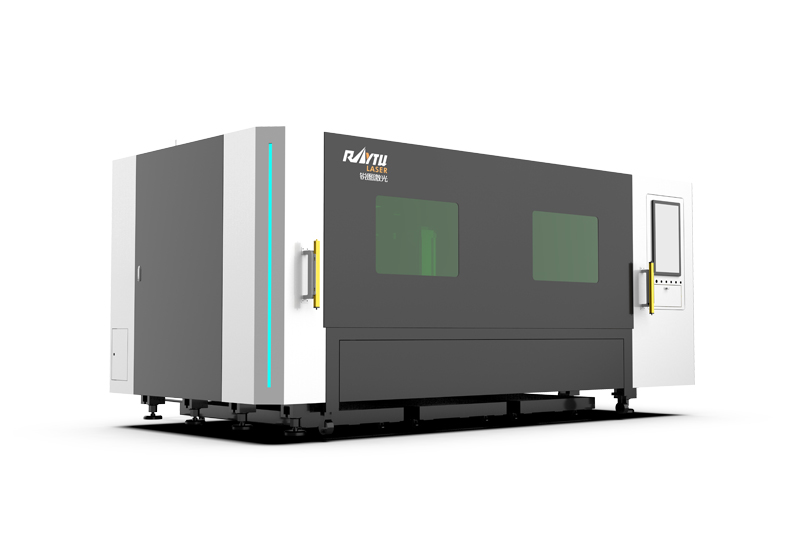

Máquina de corte por láser de fibra cerrada

Máquina de corte por láser de fibra cerrada

Máquina de corte por láser de chapa

Máquina de corte por láser de chapa

Máquina de corte por láser de metal de potencia media

Máquina de corte por láser de metal de potencia media

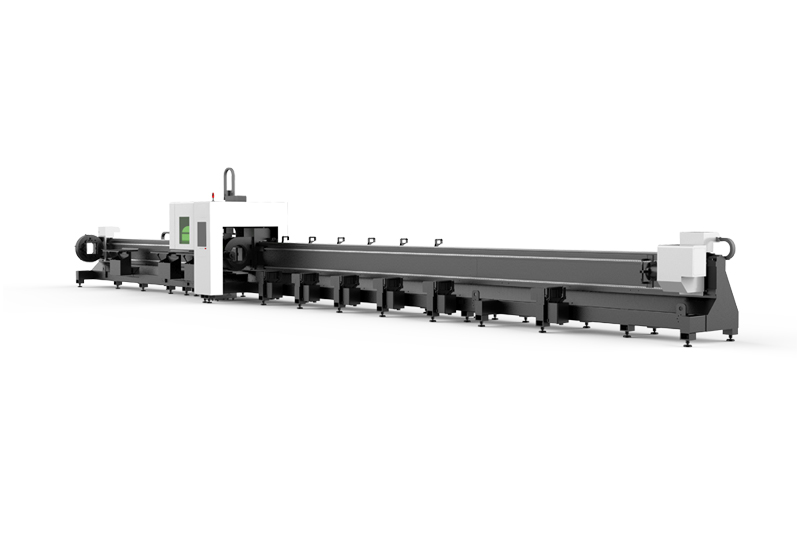

Máquina automática de corte por láser de tubos

Máquina automática de corte por láser de tubos

Máquina de corte láser de fibra de bobina

Máquina de corte láser de fibra de bobina

Máquina de corte láser de tubos de 3 mandriles RTC-12036M

Máquina de corte láser de tubos de 3 mandriles RTC-12036M

Máquina de corte por láser de fibra de mesa cerrada única

Máquina de corte por láser de fibra de mesa cerrada única

EN

EN ES

ES RU

RU AR

AR